Hello!Welcome to GuangXi Huakai Glass Company's website!

Guangxi Huakai Glass Co., Ltd.

Address: Litang town in Binyang County, Nanning Municipality of Guangxi Industrial Shigu Industrial Park

Tel: 0771 - 8246828 Fax: 0771 - 8246808

Email: zhenwutan@163.com Website: www.gxhykglass.com

Chinese - language web sites:华凯玻璃.网址

About us | Join us | Know about Huakai

Copyright: Guangxi Huakai Glass Co., Ltd.

— News Center —

Fireproof glass fire in recent years.

In recent years, both at home and abroad at a high - rise constantly, from a few years before the new CCTV tower on fire, and to the teachers' building in Jing 'an District' (Reuters) - A fire, then in the year to June 14, London residents in high - rise building fire.... after the fire, how fast it is astounding, the site seemed to have a "human purgatory.

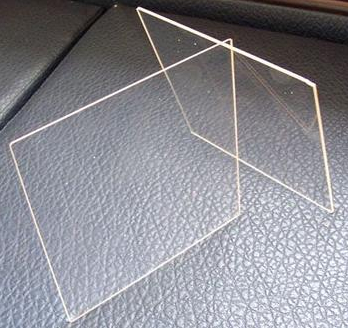

large - size curved composite fireproof glass

"several high - rise building fire alarming, China's safety in the wake - up call." As China Building Materials Research Institute, Ministry of Science Institute of the left glass and rock, the frequent occurrence of fire, the cause of the whole society for the high building fire facilities of torture.In 2015, the state promulgated a "Code of Design on Building Fire Protection, the fire control equipment such as fire - resistant windows made mandatory provisions.

In some disasters happen, if there is a better fireproof glass, whether people will be more hope for? This question has been banging on the glass of CNBM Institute Institute scientific research team.They lasted three years, Yuexiu Group showed vigourous finally put up the "hoe", broke the foreign vendors in the field of high - end market monopoly, made internationally - competitive compound.

small problems

In accordance with the divided structure, divided into a monolithic composite fireproof glass and fireproof glass.Monolithic glass not only with high costs and low - quality, and has a risk of explosion, can bring unexpected injury.In contrast, composite fireproof glass safety coefficient is high, the use of a wider, more popular on the market.

However, the excellent performance tends to necessitate higher technological content.At present, domestic composite fireproof glass of synchronous motor under the micro - bubbles are difficult to eliminate, the appearance of inferior foreign brands, and that the resistance to the ultraviolet irradiation performance is poor, the majority of the product is used outdoors for a long time, will appear dark, out of the bubble.

Composite fireproof glass core of the technique of two sheets of glass of inorganic fire retardant solution, as well as routine production techniques: direct use of the low modulus of potassium water glass as a fire retardant solution, but this substance is not chemically stable, and the transmittance is lowered, the bubbles, the flow of glue or the like defects,Influence the glass quality and appearance of the fire situation judgment.

So, will increase the modulus of potassium waterglass, can solve these problems? Glass Building Material Institute senior engineer Mu Yuanchun told reporters: "The high modulus potassium silicate solution with low solids content, viscosity, bubble discharge and spreading molding extremely difficult, and in glass preparation process can produce a lot of micro bubbles, which reduce appearance quality,fire - resistant layer cannot be directly used as the substrate. "

Thus, non - microbubbled, weatherability is excellent in high - performance composite fireproof glass, product performance is on leaps and bounds, expanding the application scope of the product, was both the fireproof glass technology development trend of building energy - saving, safety glass industrialization development...

In the full knowledge of the industry after a running sore, beginning in 2012, Mu Yuanchun team took to the inorganic composite fireproof glass research and development.

glass" core "is not vulnerable

But, the thing is not plain sailing.Composite fireproof glass fabrication technique is the mainstream of flat plate drying process, i.e., a glass is placed in the horizontal direction, may be covered with a fireproof liquid and then drying, and finally a layer of cover glass.

"It's for a special large - scale precision equipment to produce, but imports of such a set of equipment, the need to spend millions of euros." Mu Yuanchun acknowledges that, to save money, they initially all of the experiments is the "freehand".

Fire - resistant intermediate layer only 1 millimeter thick, which requires that the glass must be placed very flat, the slightest error, fire retardant solution cannot be uniformly spread.The whole team at a laboratory in the big house for a week, finally brought the error to 0. 1 mm or less.

But this still does not fully solve the microbubbles, marks and so on.Since foreign manufacturers for core technology of the blockade, the team so long to find breakthrough point, taking a lot of detours.

Until the summer of 2015, which began on.In the exchange with customers, the party will be a relatively low solids content of the silica dispersion was applied to the outer surface of the polishing of the idea.

This Muriel Yuanchun whim: if use is made of such silica dispersion liquid, directly in the glass layer with the reaction between the potassium hydroxide solution, the generation of a high modulus potassium silicate, Couldn't swoop, avoid the disadvantage of producing and airing and low modulus fireproof liquid and shortcomings?

But all this is based on the premise that it is necessary to produce a low viscosity, high solid content of the silica dispersion was achieved.If directly using conventional nano - silicon dioxide mixed with potassium hydroxide, and the viscosity is too large for shaping.

Tackling once again deadlocked.At this time, the Mu Yuanchun thought of his PhD during every step of the coating experiment, he had by means of a particle can be improved by the design of coating film - forming property of the problem."Simply put, this approach is to use a material that would put the silica particles to wrap up, so that the silica particles are not agglomerated together, but is uniformly dispersed."

At the same time requiring low viscosity and high solid content, which is almost impossible to accomplish the task.Admitting left, Mu Yuanchun was when this idea, his heart is the beat of my heart: "We ordinary people and surfaces, all know water is small, the dough will be sticky, but Mu Yuanchun set out to do, is to require little water, is added to the surface, being uniformed thin soup, a little gnocchi can ever have."

He managed to get to the advisory circle and consum 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 glass experts in the field, and it was said that it is not possible.

However, the Left Rock still choose to believe this young man.In his view, glass machining techniques are inherently multi - disciplinary intersecting, wanted to create, researchers should be encouraged.

Scientific research team of silica of particle diameter, specific surface area, the function of the monomer composition is optimized, finally conquered the low - viscosity, high solid, high - modulus potassium silicate fire retardant solution is carried out.With this new method of preparing composite fireproof glass, micro bubbles cannot physically toughening, and cannot be used for the curtain wall, not a curved surface portion and a profiled structure and the like.

In this way, Mu Yuanchun team achieve great things, developed the ultrathin inorganic composite fireproof glass.They successfully worked out to meet the national standard Class A, Class C standard requirements and the specifications of the product size, the smooth testing organizations through third - party fire endurance test assays; intellectual property aspects of a total of more than 10 patent applications including PCT International Patent Nr. 1), an authorized 3 invention patents and two utility model patents.

Growth in the "invisible champion"

This will make the production of above 5 times efficiency, reduce production costs by nearly half, price is only 1 / 3 of foreign products, it is also possible to realize the continuous production of new type composite fireproof glass preparation technology, and soon gained the favor of market.

in May 2017, CNBM Institute with new research and development of different specifications of a Novel Composite inorganic fireproof glass taking part in the Beijing China Glass, wherein large size 4200mm x 2000mm, curved structure ultrathin composite fireproof glass and has just revealed it stunning and,South - East Asia.

Cooperation with orders like snowflakes continued to arrive, due to technological problems to grasp core technology and equipment, China National Building Material Group and Institute currently has a dozen domestic consum 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 glass companies signed the agreement of the technical service to provide fire solutions, and guidance for composite fireproof glass industrial production,It is planned to produce refractory composite fireproof glass window with a 100 - million - square - foot, glass doors and give an impetus to relevant industries in the more than 15 billion yuan, of solving local glass deep processing industry is" high energy - consuming, low value - added ", has many disadvantages.

As China's oldest, most models assume, technology leading to production of a glass base, a glass court in history and created the "China first", is said to be "the cradle of China's aviation glass".In recent years, glass products for both military and civilian hospital implemented the development strategy, their innovation, adhere to the glass processing field of technology.

"We are the country's Institute, the country is badly in need of what we are striving for." Left said, "Our research team has been followed the forefront of technology, so integration going."

Currently, the Institute of Chinese ceramic glass already assumed the "13th Five - Year national key research and development plan for" smart glass safety glass with a high function of the key technology of the Project, will continue to perfect fireproof glass production technology, the drafting of relevant industrial standards, the establishment of the brewing industry allianceChina to push for fireproof glass, the restructuring of industry and the orderly and sustainable development.

Three years does not fly, it will soar to not sung for three years, but how.With Mu Yuanchun team of Innovation and Technology, Institute of Chinese ceramic composite fireproof glass field resulted in the successful implementation of "Counterattack", not only growing in the field of "Invisible Champion", but also in relation to the safety of the people and the key technology in the field earned a truly fireproof glass Chinese "fire".